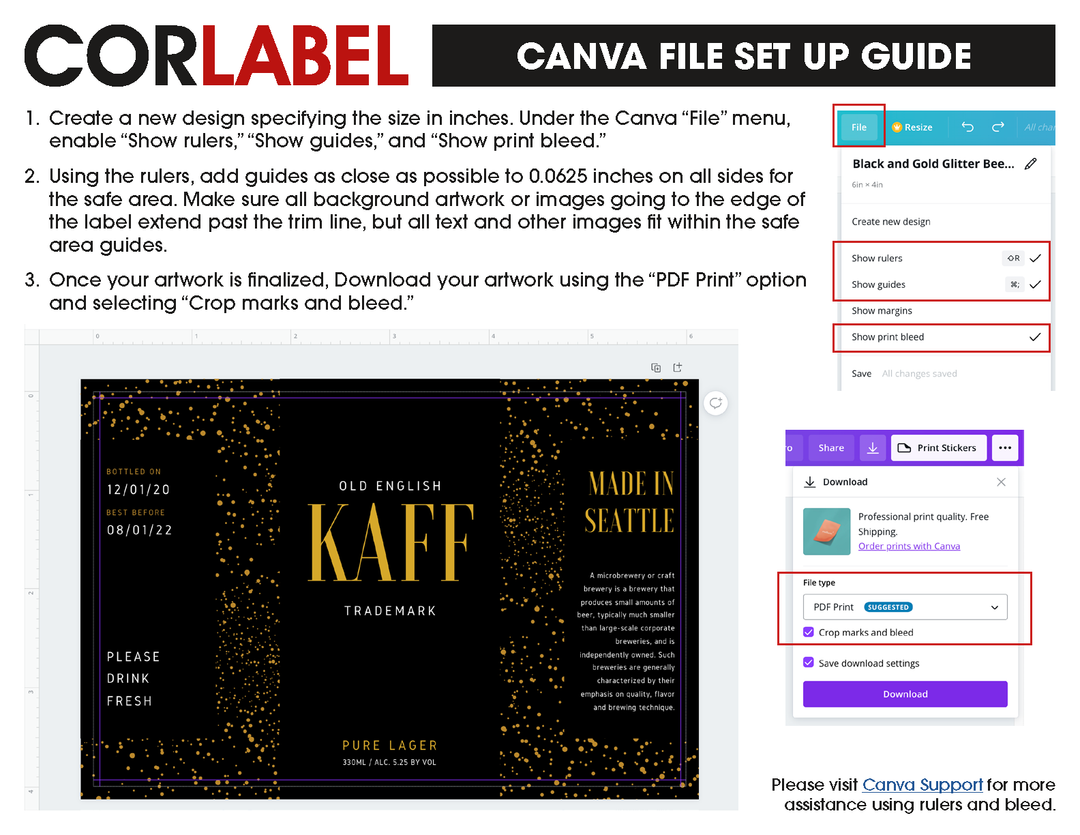

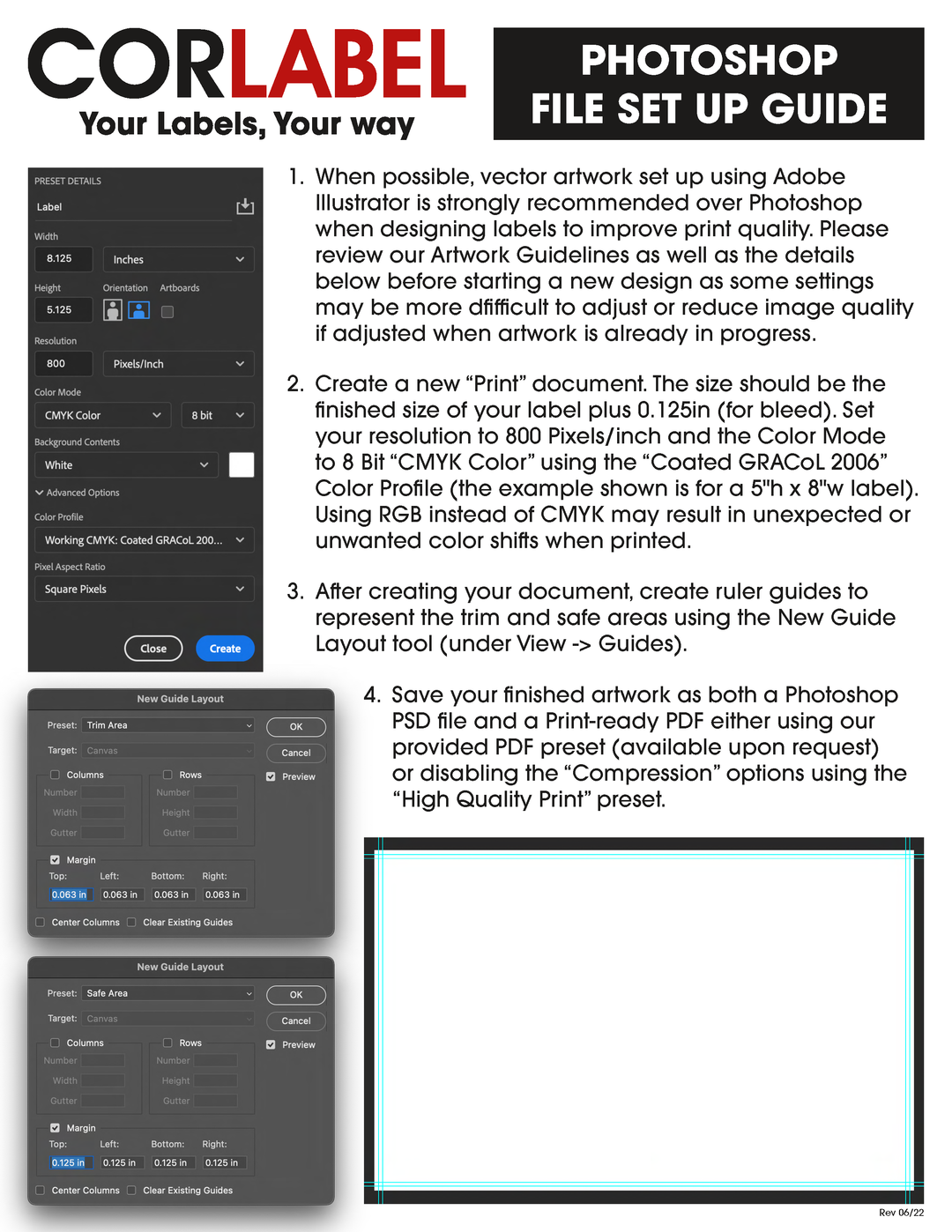

File Setup Guide by Type

Click the button below to download the guide for how-to setup your file based on your design software

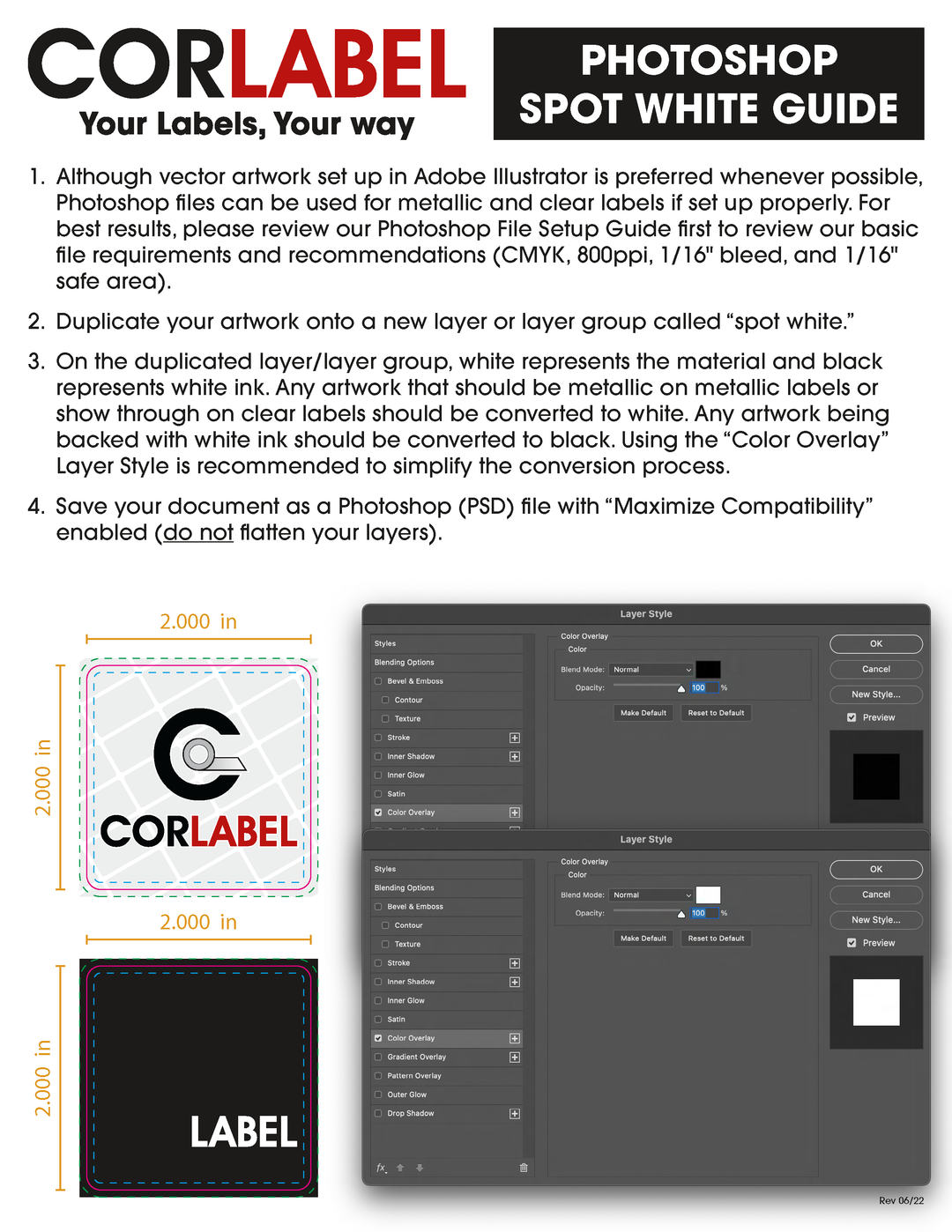

Photoshop Spot White Guide

Photoshop File Setup Guide for Metallic, Clear and Holographic Labels

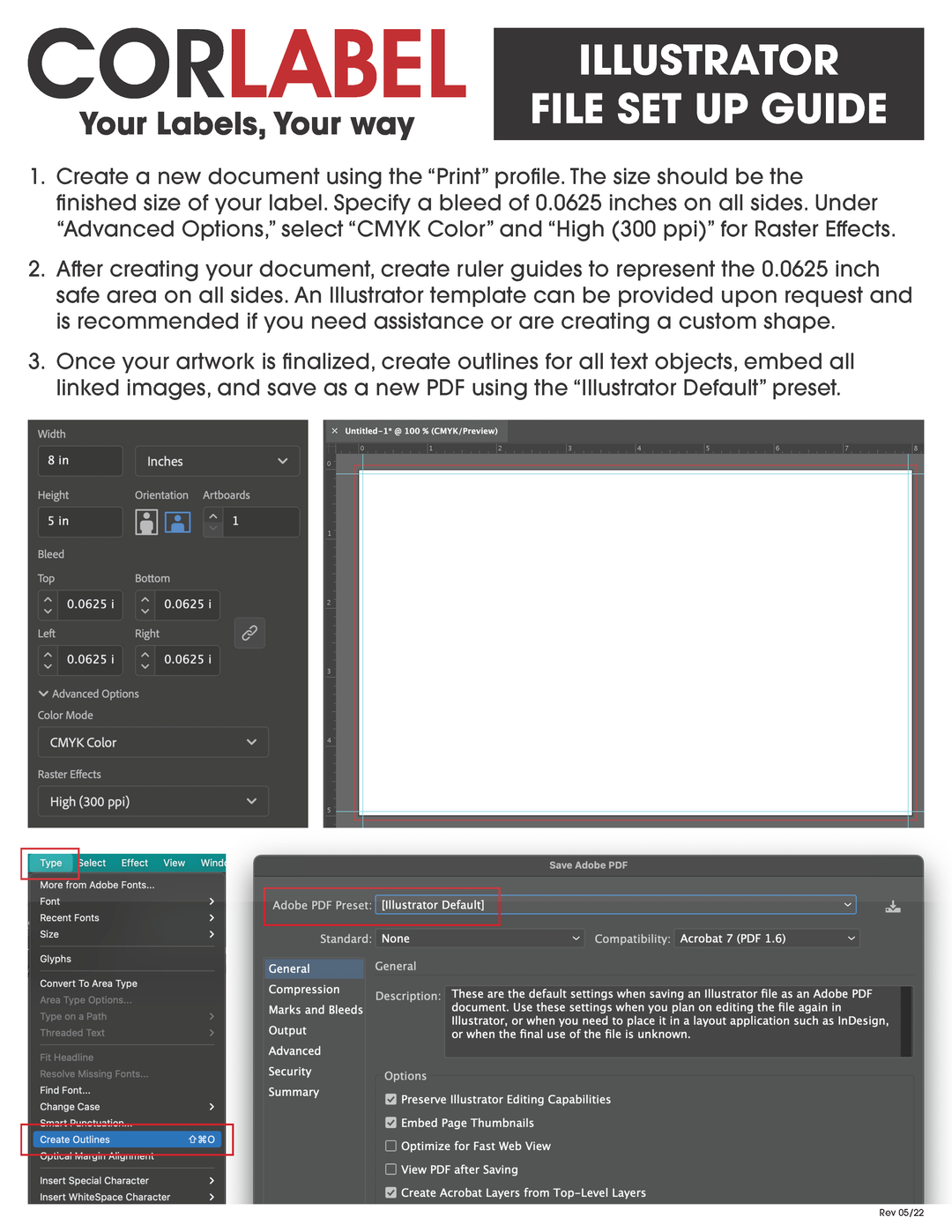

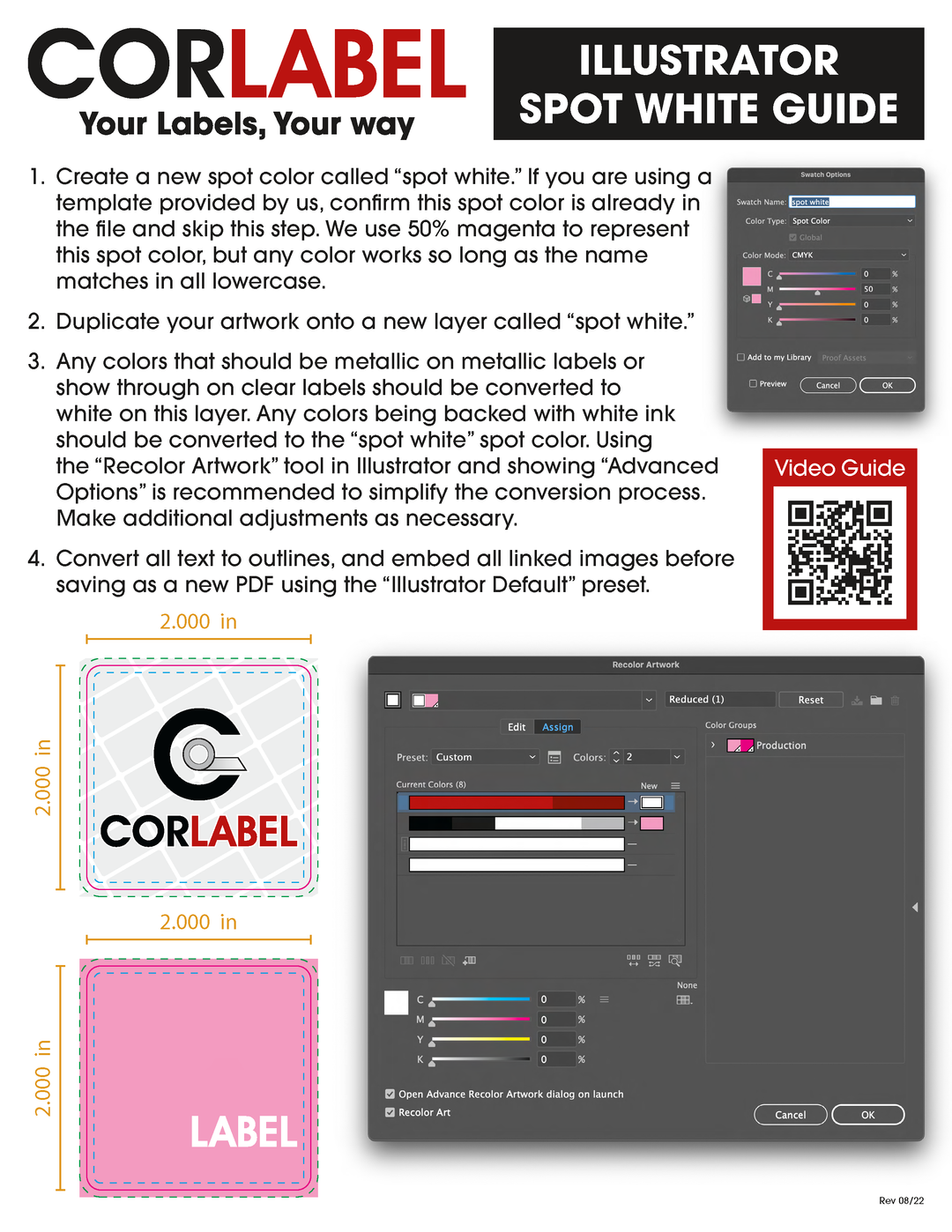

Illustrator Spot White Guide

Illustrator File Setup Guide for Metallic, Clear and Holographic Labels

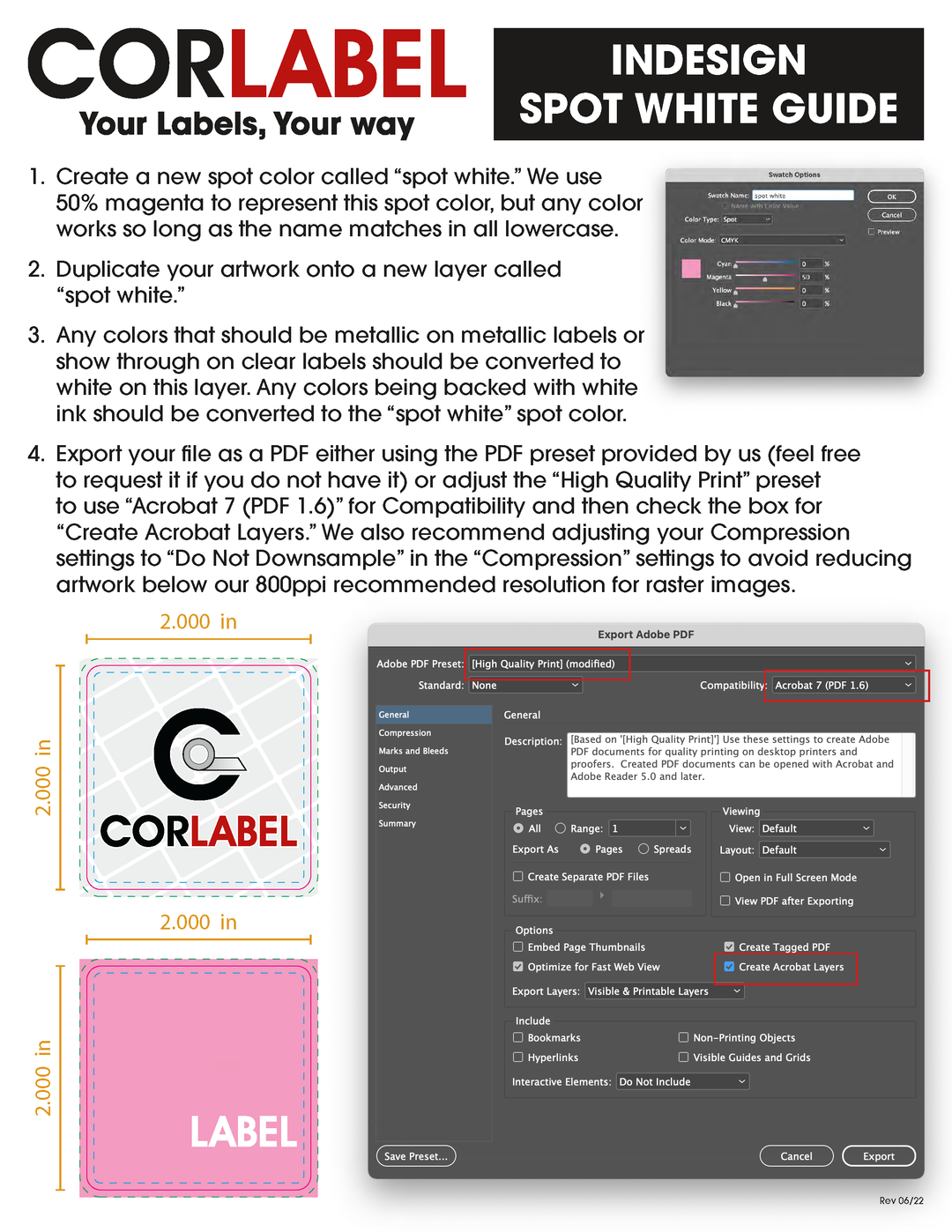

InDesign Spot White Guide

InDesign File Setup Guide for Metallic, Clear and Holographic Labels

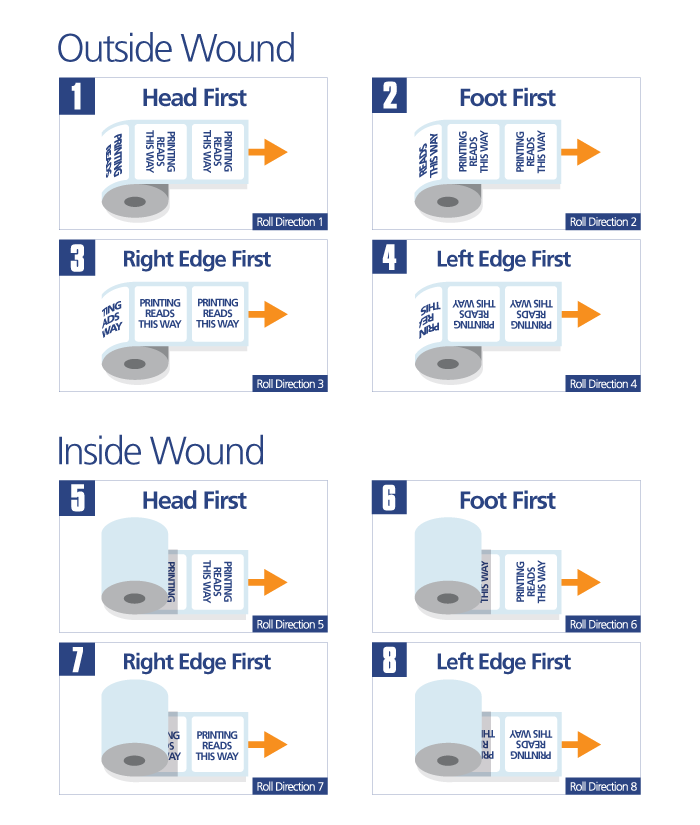

What is unwind direction and how do I determine it?

Unwind direction refers to the orientation in which the label comes off the roll when it is being dispensed or applied to the product. It is an essential consideration in label printing and application processes to ensure that the labels are correctly positioned and oriented for application.

The unwind direction is represented by numbers typically (unwind #1, #2, #3, #4,) however it is important to note there are a total of 8 unwind directions. Each number corresponds to a specific way the labels unwind from the roll. The specific unwind direction is crucial to match the requirements of your labeling machinery or co-packing process. Here's how to determine the correct unwind direction:

● Consult Your Co-Packer or Machine Specs: If you are working with a co-packer or using label application machinery, they will likely specify the required unwind direction for the labels. Co-packers and labeling machines are designed to work with specific unwind orientations, ensuring smooth and efficient application.

● Understand the Unwind Direction Numbering: The unwind direction is typically represented by numbers 1 to 8, each corresponding to a specific orientation. For example, unwind #1 might mean the label unwinds from the top of the roll, while unwind #3 might indicate the label unwinds from the bottom of the roll.

Unwind Directions

Choosing the correct unwind direction is vital to ensure efficient label application and avoid any misalignment or issues during the labeling process. By understanding your co-packer's or machinery's requirements and communicating them clearly to the label manufacturer, you can ensure that your labels are supplied in the appropriate unwind orientation for your specific application needs.

Other guidelines to consider:

- Rounded Corner Rectangles: Rounded corner rectangles are labels with rounded corners on the die size. The corners of the label have a smooth, curved shape rather than sharp angles. This creates a softer appearance for the label.

- Square Corners: Square corners refer to labels with squared-off corners on the die size. The corners form perfect 90-degree angles, creating a clean and sharp look for the label.

Both rounded corner rectangles and square corners have their unique visual characteristics, and the choice between them depends on the desired aesthetics and brand identity for your labels. Rounded corners tend to create a modern and friendly feel, while square corners offer a more traditional look.

CMYK (Cyan, Magenta, Yellow, Black) is a color model used in printing to reproduce a wide range of colors by mixing different percentages of these four ink colors. It is also known as the "4 color process" because it uses these four primary ink colors to create a full-color image.

In the CMYK color model:

- Cyan absorbs red light and reflects blue and green light.

- Magenta absorbs green light and reflects red and blue light.

- Yellow absorbs blue light and reflects red and green light.

- Black, represented by "K" in CMYK, is used to add depth and improve contrast in the final printed image.

When printing in CMYK, tiny dots of these four ink colors are applied in varying densities to create a wide spectrum of colors, shades, and tones. By overlapping the dots in different patterns, the printer can produce the illusion of continuous tones and reproduce high-quality images and graphics.

CMYK printing is commonly used in the printing industry for producing full-color materials like brochures, labels, magazines, and other marketing materials. It is the standard color model for most digital and offset printing processes.

When designing your labels, it is essential to work in the CMYK color space to ensure the colors you choose on your computer screen accurately translate to the printed labels. Some colors that are easily represented on digital screens (using the RGB color model) may appear differently when printed in CMYK, so it's essential to check proofs and test prints to achieve the desired color accuracy and quality for your labels.

Choosing the size of your label is an important decision that should be based on several factors to ensure it fits your application and enhances the overall presentation of your product. Here are some steps to help you determine the appropriate label size:

- Understand the Purpose: Consider the primary purpose of the label. Are you using it for branding, product information, instructions, or regulatory compliance? The purpose will influence the amount of content you need to include on the label and, consequently, the required size.

- Measure the Container: Measure the available surface area on your product container where you intend to place the label. Be mindful of any curves, ridges, or irregularities that might affect label application.

- Contact the Container Company: Reaching out to the container company is a good idea. They often have experience with labels and can provide guidance on recommended label sizes for their specific containers.

- Mock-Up with Paper Cutouts: Create paper cutouts or templates of different label sizes and shapes. Place them on your product container to visualize how they will look and how well they fit. This will help you visualize the final result before committing to a specific size.

- Consider the Design: Your label size should complement your design and content. Ensure that the text, images, and branding elements remain clear and legible at the chosen size.

- Die Lines and Artwork: Provide us with your specific artwork, we can create die lines to fit your artwork inside. This ensures that your design fits perfectly within the label's boundaries.

- Line Trial: Before placing a full order, consider requesting a line trial from us. This allows you to test the label application process and see the finished look on your actual product. It's an essential step to identify any potential issues before mass production.

- Regulatory Requirements: If your product requires specific information, such as legal disclaimers or regulatory labels, ensure there is enough space to accommodate this information while maintaining compliance with relevant regulations.

- Branding and Visibility: The label size can impact your product's visibility on the shelves. Consider how your label size affects your branding and the ability to catch consumers' attention.

- Customization: We offer customization options, so don't feel restricted by standard sizes. If a custom size better suits your needs, discuss it with us.

By considering these factors, you can choose the right label size that not only fits your product container but also effectively communicates your brand message and product information to your target audience.